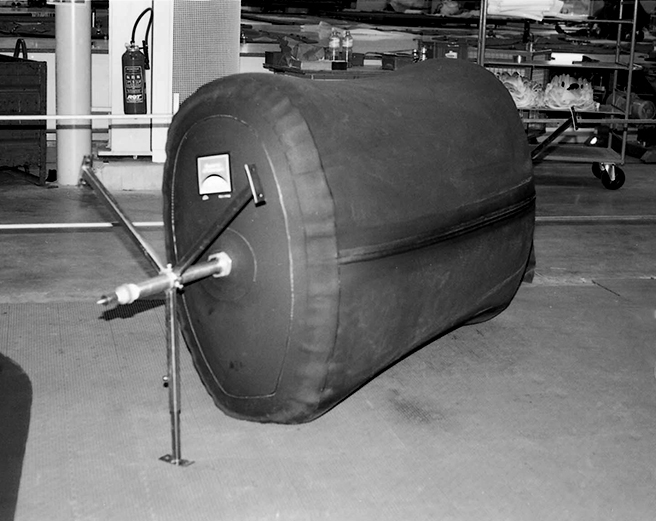

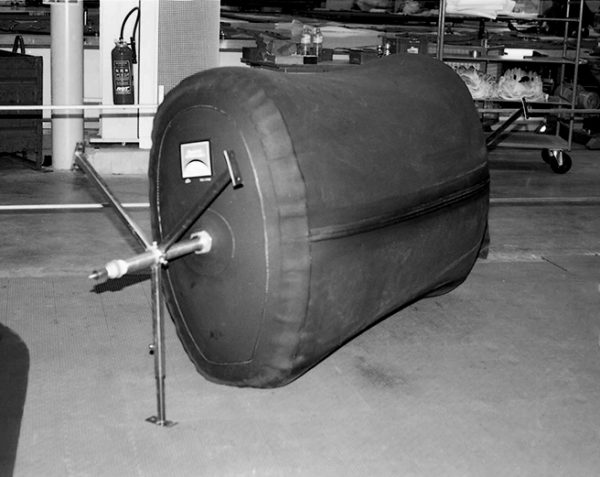

Egg shaped test plug - OVO

The egg shaped test plug OVO is used to close ovoid pipes and ovoid sections. These plugs are also suitable for water and air tightness tests according to DIN 4263 and NF P16-401.

These pneumatic sealing systems can be equipped with bypass tubes. Indeed, this tube ensures the passage of gas or fluids during maintenance or testing.

Moreover, it is made of a high resistance textile frame coated with vulcanized neoprene and assembled by cold gluing. The egg-shaped test plug is light, strong, resistant and quick to install.

Advantages

Reliability

- Low cost

- Total tightness

- Extremely durable

Safety

- Secure inflation

- Highly resistant

- DIN 4263 and NF P16-401 Standards

Installation

- Rapid installation

Detailed information

- Material: Coated fabric 1200 daN/5 cm

- Technique: cold glue assembly

- Length: 600 > 2400 mm

- Inflation: by air

- Temperature resistance: -20 to +60°C (please contact us for any use outside of this temperature range)

- Max. inflation pressure: 0.8 bar

- Max. back-pressure: 0.5 bar

- Accessory: 1 x 3/4″ valve in the center of a base

Technical informations

| Ref. | Internal dimensions of the tube (Length in mm) | Internal dimensions of the tube (Height in mm) | Oval length (mm) | Approx. weight of oval (kg) | Max. inflation pressure (bar) | Max. back-pressure (bar) | Standard |

|---|---|---|---|---|---|---|---|

| S 30 | 300 | 450 | 600 | 20 | 0.8 | 0.5 | DIN 4263 |

| S 40 | 400 | 600 | 800 | 22 | 0.8 | 0.5 | DIN 4263 |

| S 50 | 500 | 750 | 1000 | 23 | 0.8 | 0.5 | DIN 4263 |

| S 55 | 550 | 1000 | 1300 | 24 | 0.8 | 0.5 | DIN 4263 |

| S 60 | 600 | 900 | 1200 | 26 | 0.8 | 0.5 | DIN 4263 |

| S 70 | 700 | 1050 | 1400 | 28 | 0.8 | 0.5 | DIN 4263 |

| S 80 | 800 | 1200 | 1600 | 32 | 0.8 | 0.2 | DIN 4263 |

| S 90 | 900 | 1350 | 1800 | 36 | 0.8 | 0.2 | DIN 4263 |

| S 100 | 1000 | 1500 | 2000 | 45 | 0.8 | 0.2 | DIN 4263 |

| S 120 | 1200 | 1800 | 2400 | 60 | 0.8 | 0.2 | DIN 4263 |

| T100 | 625 | 1000 | 1300 | 28 | 0.8 | 0.5 | NF P16-401 |

| T130 | 800 | 1300 | 1700 | 36 | 0.8 | 0.5 | NF P16-401 |

| T150 | 900 | 1500 | 2000 | 45 | 0.8 | 0.2 | NF P16-401 |

| T180 | 1080 | 1800 | 2350 | 60 | 0.8 | 0.2 | NF P16-401 |

| T200 | 1200 | 2000 | 2600 | 65 | 0.8 | 0.2 | NF P16-401 |

You can not find your dimensions

Our design department employs the best project leaders and designers and will be pleased to develop and create a tailor-made product specially for your unique project.