Inflatable system for GSS hydraulic testing

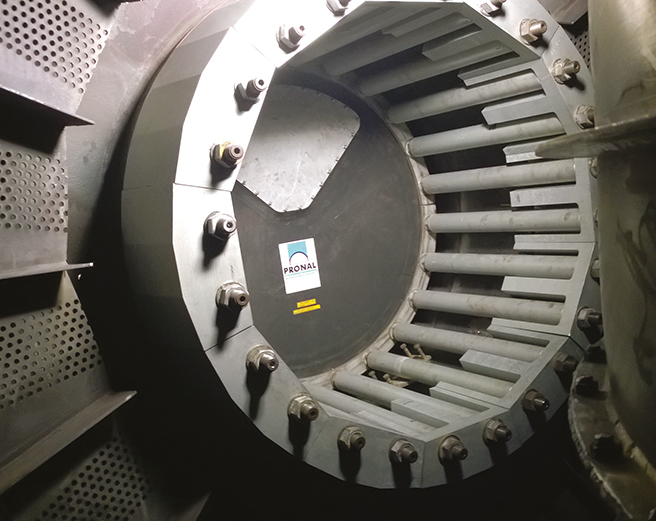

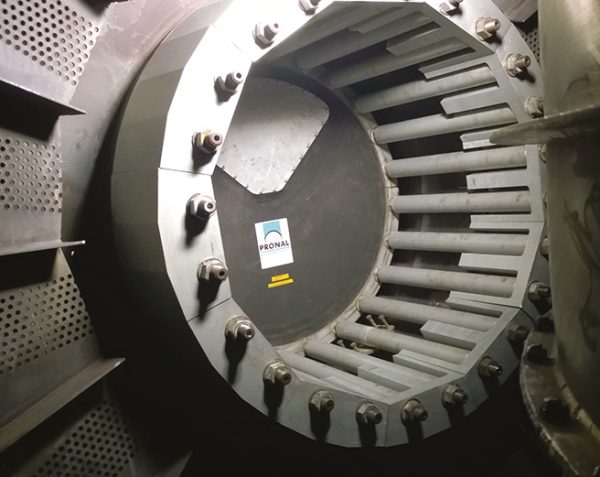

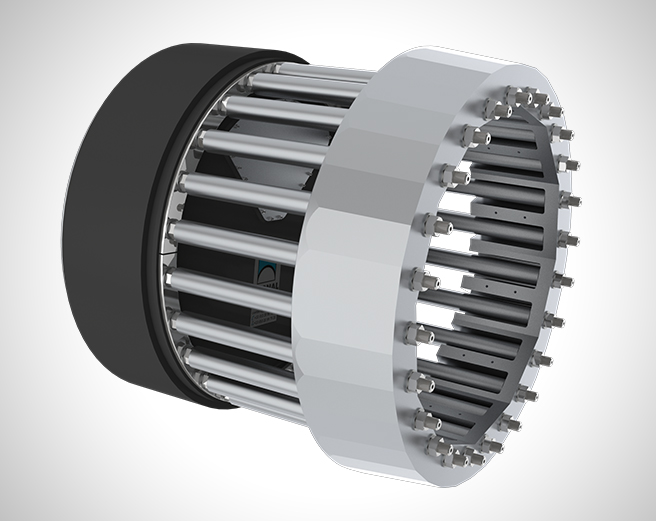

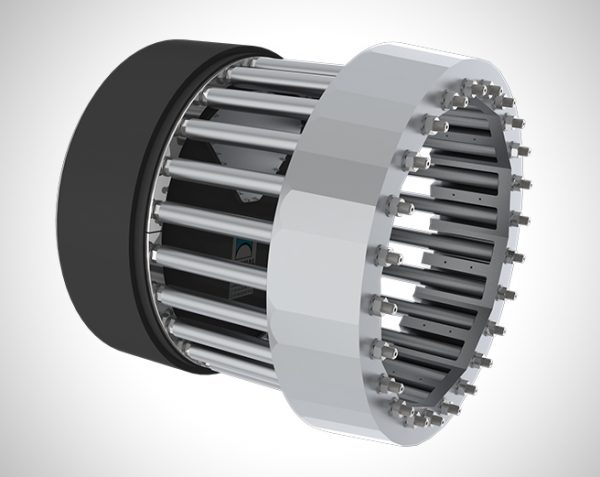

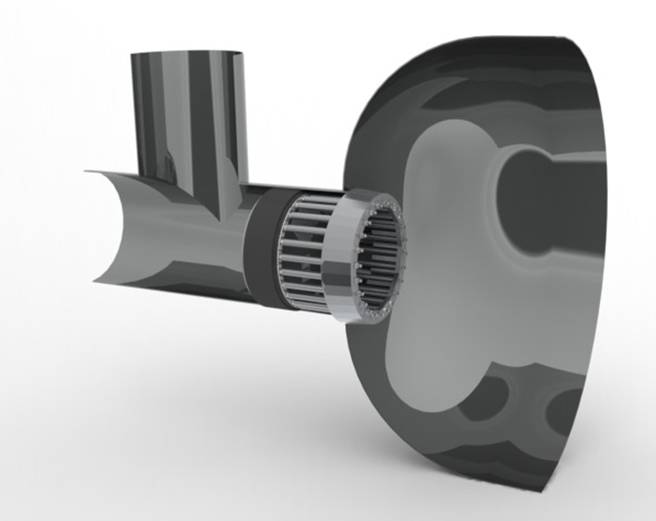

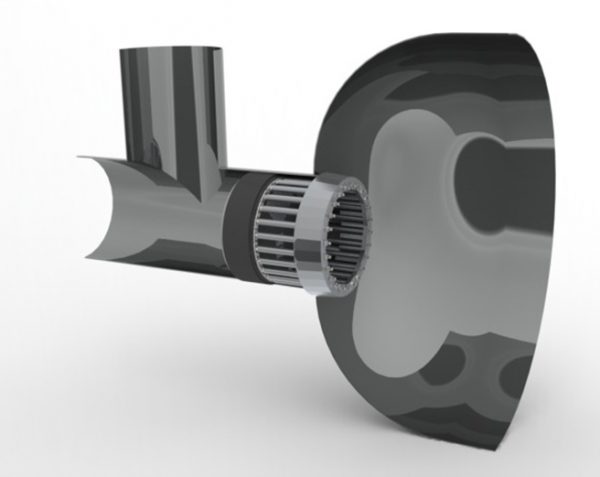

Pronal has designed an inflatable stopper system for implementing hydraulic tests on superheater dryer units (GSS). This system is a combination of two solutions:

- An inflatable stopper which plugs the outlet on the side of the VISM valve (OHP),

- And on the other side, an inflatable jack mounted on a metal support is inserted into the outlet of the GSS grille. This solution can be completely dismantled.

This removable system is installed via a manhole with a 400 mm diameter. The test pressure reaches around 25.5 bar. Testing is validated on-site by a certifying company. This inflatable pipe plug is mostly used on nuclear sites.

The GSS hydraulic testing serves to certify the strength and tightness of the GSS grille. This Pronal inflatable stopper system reduces outage time by avoiding cutting/welding pipework that could also include the fitting of welded caps.

Avantages

Use

- Dissociation of the load-bearing and the tightness

- Fully removable system

- Adjustable depending on the configuration of the GSS tapping

Safety

- Tightness of inflatable seals and stoppers

- High quality and resistance

Handling

- Easily and rapidly installed

- No cutting/welding operations so no TIR radiation

- 5 workers: 3 days required for assembly/2 days for dismantling

- Equipment reconditioned using our test bench

Informations détaillées

- Material:

- Cylinder ring in NPVC

- SBR (Styrene Butadiene Rubber) for the OHP2

- Technique: hot vulcanisation in a vacuum autoclave

- Dimensions:

- Dia. 1150 mm for the cylinder

- Dia. 920 mm for the stopper

- Form: cylindrical

- Inflation: by water

- Max. inflation pressure:

- 38 bar for the inflatable seal

- 35 bar for the stopper

Vous ne trouvez pas vos dimensions

Notre bureau d'études composé des meilleurs chefs de projets et de desssinateurs sauront imaginer et créer un produit sur-mesure spécialement pour vous et votre projet unique.