As part of the safety regulations for a nuclear unit, our customer EDF needed a fast and economical system to test its GSS calanders by performing hydraulic tests. These hydraulic tests ensure that the structure is perfectly watertight and has the required strength to withstand operating conditions. Therefore, we have proposed to them our plugs specially designed for this application: the inflatable system for GSS hydraulic testing.

CONSTRAINTS FOR TESTING GSS CALANDERS FOR NUCLEAR POWER PLANTS

The problems were :

- The pressure of the test at 25 bars

- A large diameter of the pipes : Ø946 mm and Ø1176 mm

- The Ø400 mm manhole for the Ø1176 mm

Until now, the company EDF had to cut the pipes to install caps (welded metal plugs) and carry out X-ray shots to check the conformity and the tightness of the welds.

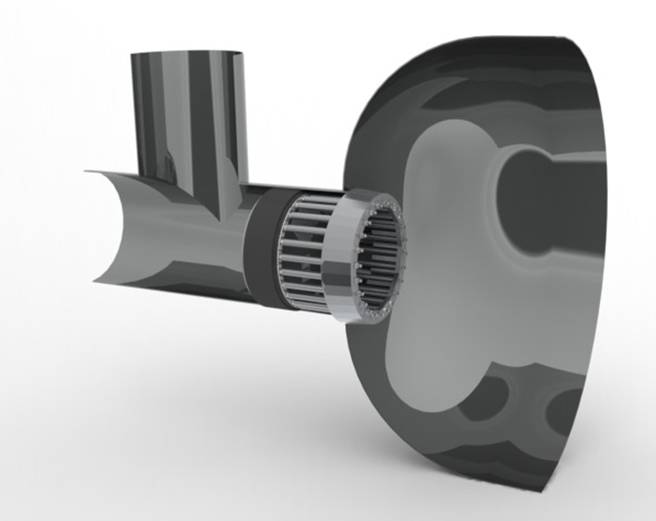

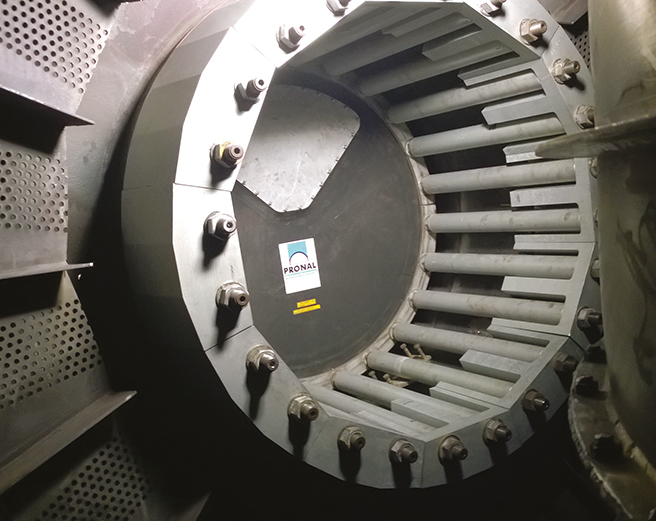

Pronal solution : INFLATABLE SYSTEM FOR GSS HYDRAULIC TESTING

To meet this need, Pronal supplied OHP high pressure inflatable pipe plugs for the Ø946 mm pipes. For the Ø1176 mm manhole, an inflatable system for GSS hydraulic testing were supplied. The installation and commissioning on site of these flexible solutions for testing the GSS calenders was handled by our service teams.

After the hydraulic test was completed, the used pneumatic plugs could be repackaged and stored in our premises until the next test.

Conclusion

By using this inflatable sealing system, EDF was able to :

- preserve its pipes (no more cutting to install the caps),

- facilitate the hydraulic test (no more radio shots to check the welds),

- save time, i.e. 30 days per unit shutdown,

- and reduce the costs associated with the hydraulic test.

It takes 2 to 3 days to install a set of 3 x 920 plugs and 2 x 1200 plugs (required to test a GSS), saving the operator about 30 days of outage time.

With this solution, Pronal won the DPN (nuclear fleet management) challenge in 2014.

Vous souhaitez plus d'informations sur ce projet ?

Vous pouvez contacter nos experts qui sont adeptes de ce genre de projet pour avoir plus d’informations et être conseillé