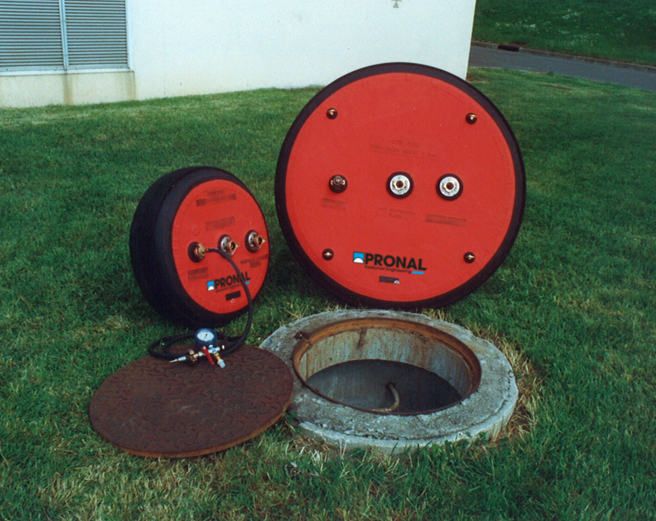

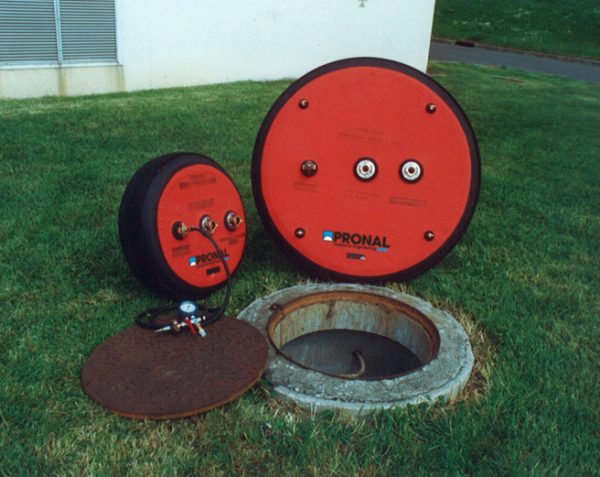

PIPE TEST PLUG- OTR

The pipe test plug OTR is designed to test the tightness of inspection wells that are found in waste-water systems. Flexible and light, you can easily integrate it in the sewerage network. Moreover, its execution is very fast.

Whatever the diameter of the pipe, the height of the sealing balloons is 200 mm. This allows a simple and fast use in narrow spaces.

Thanks to a double-walled fabric and a hot vulcanization in the autoclave, the pipe test plug allows a perfect sealing. It also offers a high resistance to wear and tear and therefore a long service life.

In addition, the pipe plug is equipped with through walls for pressurization, intended for manhole tightness tests.

In the range of inflatable pipe plugs dedicated to sanitation, there is also the standard inflatable pipe plug OPL.

Avantages

Reliability

- Total tightness

- Extremely durable

Safety

- Safety

- Highly wear-resistant

Installation

- Rapid installation

Informations détaillées

- Material: double layered 200 mm NPVC fabric on a polyester backing

- Technique: hot vulcanization in a vacuum autoclave

- Max. height. :200 mm

- Inflation: by air

- Temperature resistance: -25 to +85°C (please contact us for any use outside this temperature range)

- Inflation pressure: max. 1 bar

- Back-pressure: 0.1 bar

- Supplied accessories:

- 1 x ¾’’ G quick connector for inflating the stopper

- 1 x ¼’’ G CEJN coupler for checking the pressure

- 1 x DN 20 Camlock adapter for pressurizing the pipe

- 4 hoisting rings.

Informations techniques

| Ref. | External Ø (mm) | Internal Ø of inspection well (mm) | Height (mm) | Weight (kg) | Inflation pressure (bar) | Back-pressure (bar) |

|---|---|---|---|---|---|---|

| OTR 250 (on metal collar) | 243 | 250 | 45 | 3 | 0.1 | |

| OTR 300 | 280 | 300+/-10 | 200 | 3.5 | 1 | 0.1 |

| OTR 600 | 580 | 600+/-10 | 200 | 5 | 1 | 0.1 |

| OTR 650 | 630 | 650+/-10 | 200 | 7 | 1 | 0.1 |

| OTR 600/650 | 580 | 610/650 | 400 | 8 | 1 | 0.1 |

| OTR 800 | 780 | 800+/-10 | 200 | 6 | 1 | 0.1 |

| OTR 1000 | 980 | 1000+/-10 | 200 | 7 | 1 | 0.1 |

Vous ne trouvez pas vos dimensions

Notre bureau d'études composé des meilleurs chefs de projets et de desssinateurs sauront imaginer et créer un produit sur-mesure spécialement pour vous et votre projet unique.