Emergency pipe plug diameter smaller than 1000mm - OPAP

Sensitive to environmental protection, Pronal has developed an emergency pipe plug called OPAP. We can also call it an anti-pollution pipe plug. It is used for diameters below 1000 mm. For larger diameters, we invite you to look at the OFR range of emergency pipe plugs.

In case of disaster, this plug can quickly stop any accidental pollution.

This system is in line with the risk prevention as described in article 13 of the decree of 5/08/2002. Relating to the prevention of the disasters in the companies, this article imposes to the establishments, to equip their networks of collection of effluents and rainwater, of systems of obturation to maintain any accidental pollution.

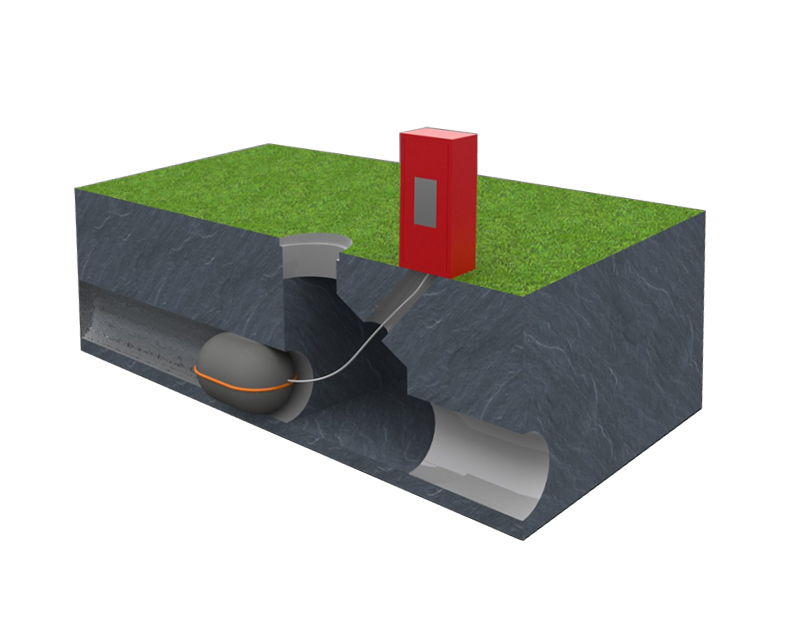

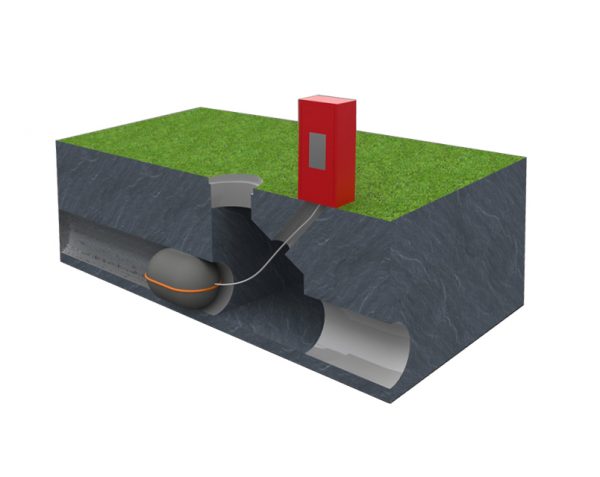

In addition, its installation is simple and does not require major civil engineering work. The emergency pipe plug is permanently installed in the pipes. It is maintained in the upper part of the pipe and does not interfere with the water flow.

Once installed, the plugging balloon is connected, by a flexible hose, to a control box near the manhole. It can be triggered manually in the box, or automatically using a remote electric control or a GSM remote control. Thanks to this control box we can inflate and deflate the pipe plug the shutter remotely. This system prevents the operator from going down in the pipe.

To know more about it, you can read this article: HOW TO USE AN EMERGENCY PIPE PLUG ?

Avantages

Use

- Excellent chemical compatibility

- Rapid inflation (manually or automatic)

Safety

- Complies with Article 13 of the Decree published on the 5/08/2002 concerning the prevention of corporate accidents

- Environmental protection

Installation

- Requires no major civil engineering work

- Rapid and economical installation

Informations détaillées

- Material: NBR/NPVC rubber

- Technique: vulcanization

- Length when deflated: 550>2050 mm

- Diameter: 150 > 1000 mm

- Tailor-made dimensions possible; contact us

- Inflation: by air

- Temperature resistance: -25°C à +85°C

- Inflation pressure: max. 1.2 bar

- Accessory: 1 x 1/4″ or 3/4″ valve (when greater than 600 mm)

- Manual or Remote red painted steel control unit

Informations techniques

| Ref. | Stopper diameter (mm) | Width when deflated (mm) | Length when deflated (mm) | Service pressure (bar) | Inflation insert (") |

|---|---|---|---|---|---|

| OPAP 100 | 100 | 161 | 230 | 1.2 | 1/4" |

| OPAP 150 | 150 | 239 | 345 | 1.2 | 1/4" |

| OPAP 200 | 200 | 318 | 460 | 1.2 | 1/4" |

| OPAP 250 | 250 | 397 | 575 | 1.2 | 1/4" |

| OPAP 300 | 300 | 475 | 690 | 1.2 | 1/4'' |

| OPAP 400 | 400 | 632 | 920 | 1.2 | 1/4" |

| OPAP 500 | 500 | 789 | 1150 | 1.2 | 1/4" |

| OPAP 600 | 600 | 946 | 1380 | 1 | 1/4" |

| OPAP 700 | 700 | 1103 | 1610 | 0.8 | 3/4" |

| OPAP 800 | 800 | 1260 | 1840 | 0.6 | 3/4" |

| OPAP 1000 | 1000 | 1574 | 2300 | 0.4 | 3/4" |

Vous ne trouvez pas vos dimensions

Notre bureau d'études composé des meilleurs chefs de projets et de desssinateurs sauront imaginer et créer un produit sur-mesure spécialement pour vous et votre projet unique.